Recycling Propels the Circular Economy

As a leading global recycler of steel, our operations support the circular economy by reducing scrap metal sent to landfills. Our recycling facilities collect end-of-life materials from individuals, commercial companies and scrap yards, along with pre-consumer scrap from manufacturing facilities, which are processed to use as raw material at our mills.

We also work to reduce waste sent to landfills by recycling metals that can be used as raw materials for new products in a variety of industries. In our shredding and scrap recycling processes, we separate ferrous material that contains iron from nonferrous metals such as copper, brass and aluminum, which are then recycled for use as raw materials for new products used in construction, automotive and aviation.

In our manufacturing operations, we capture and recycle coproducts and byproducts such as steel slag used by construction companies as a base materials in highways, asphalt and other products. We capture and recycle 99% of the baghouse dust from our EAF furnaces, which contains zinc and other valuable metals used to create products such as paints, tire rubber and fertilizers.

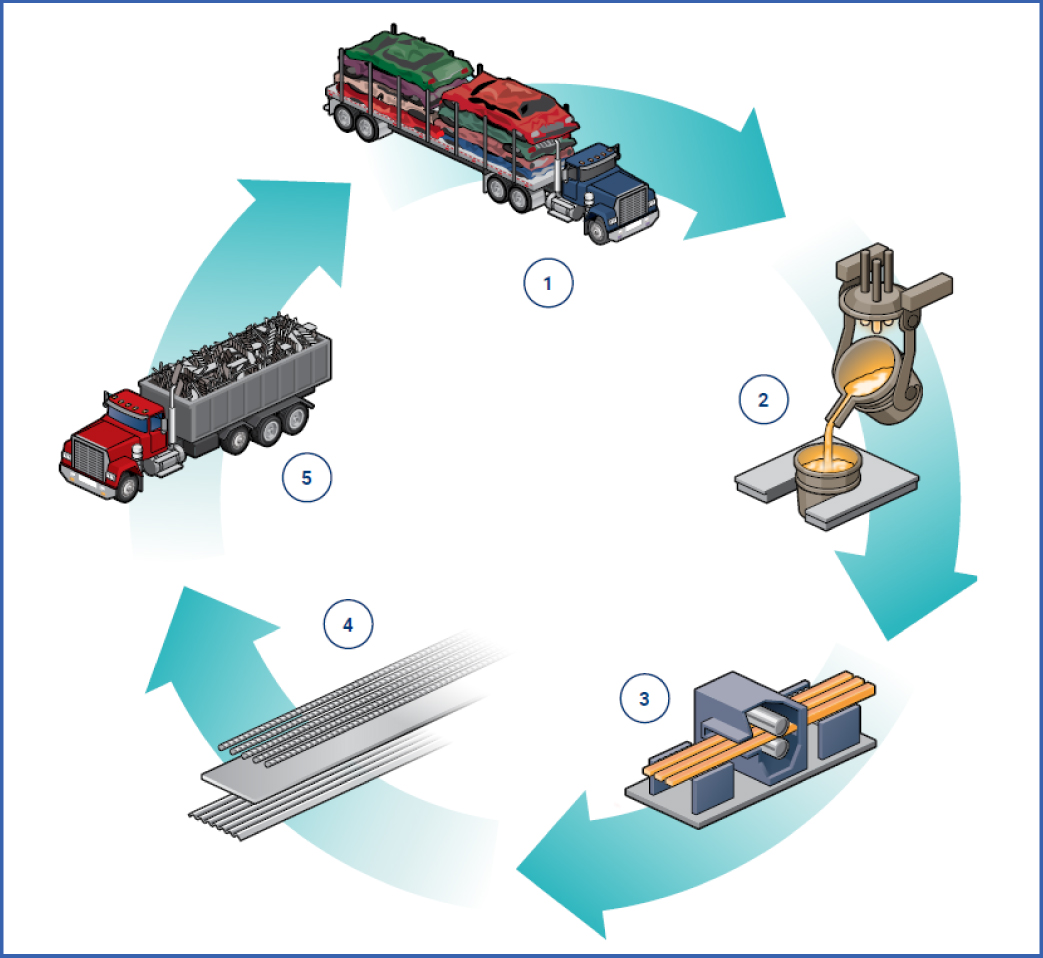

Contributing to Circularity

- We start by locally sourcing, purchasing and processing scrap metal from various sources. Our shredding and scrap recycling processes separate nonferrous recyclable metals (e.g., copper, brass and aluminum) from ferrous metal that can be remade into new products used in buildings, automobiles, roads, bridges and more.

- We melt recycled scrap metal into new steel using our state-of-the-art EAF technology.

- We then roll the new steel into finished long steel products.

- We produce finished products in various shapes and lengths and further fabricate some for the many markets we serve.

- We reclaim end-of-life steel material as feedstock, restarting our cycle of steel production, creating a complete closed-loop system.